Gypsum Board

Moisture Control for Gypsum Board

Moisture Measurement and Control is an essential tool for Gypsum Board Manufacturers looking for precision dryer balancing, increasing product consistency, dropping energy costs, reducing product waste, and improving product quality.

If you work in the gypsum manufacturing industry you have heard of Sensortech. We are the industry standard for moisture measurement and control and have been the global leaders for over 30 years for good reason.

Gypsum Board Sensors

IMPS-4400

Instant Moisture Profiling System

ST-3300

Moisture Management System

PMT-330

Portable Moisture Tester

NIR-7000

Near Infrared Analyzer

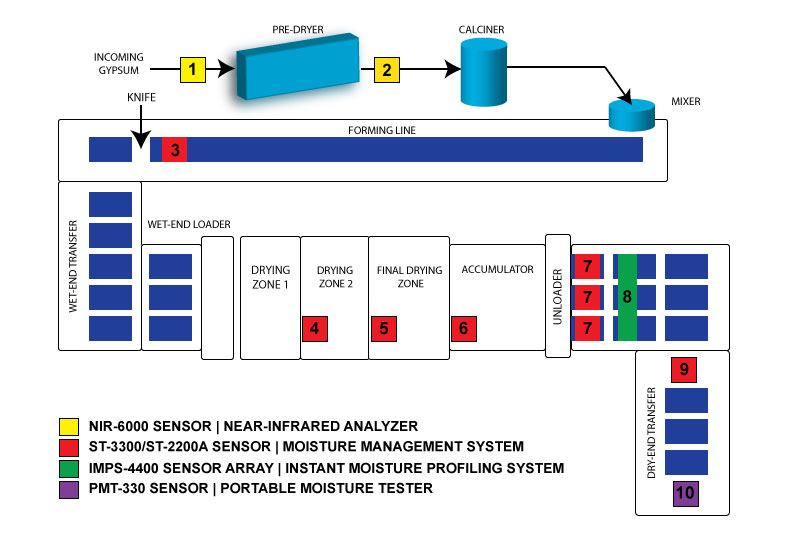

Gypsum Board Process Diagram

Complete Moisture Process Control

- Infeed Sensor

Monitors the incoming raw gypsum adds value to your process by providing a feed-forward control mechanism allowing you to actively predict drying speed and temperature for optimum control. - Crushed Rock Sensor

Works in conjunction with the Infeed Sensor by providing useful feedback data that correlates to the overall performance of the drying system. Having this information facilitates energy efficiency as well as a quality controlled material feed into the calciner. - Wet-End Sensor

Measures gypsum board moisture for an early indication of dryer load. - Ultra High Temperature Sensor

Measures gypsum board moisture at the end of Zone 1 or start of Zone 2. Provides feed forward information for Zone 2 drying. Operates in temperatures up to 1000°F (540°C). - High Temperature Sensor

Measures gypsum board moisture at the Final Drying Zone. Provides feed forward control of the Final Drying Zone and trim on Zone 2. Typically operates in temperatures of 392°F (200°C). - End of Kiln Sensor

Measures the gypsum board moisture at the Accumulator Section. Provides feed back information for the trimming of the Final Drying Zone. Typically operates in temperatures of 302°F (150°C). - Out of Kiln Sensor

Measures finished board moisture. One sensor provides a moisture measurement for one board stream. Provides Final Drying Zone trimming and facilitates dryer balancing. - Moisture Profiling Sensors

Provides a detailed moisture distribution of the gypsum board. This is the most advanced level of moisture control available for gypsum board manufacturers. - Transfer Sensor

Provides a cross board profile of gypsum board. - Hand Held Sensor

Provides accurate spot checking of gypsum board. Portable moisture tester that is lightweight, rechargeable, and stores multiple calibrations.