About RF Technology

RF Technology

Radio Frequency (RF) technology uses an RF Dielectric Measurement to analyze the moisture composition of your product. The effect of moisture distribution is greatly minimized due to the RF energy deeply penetrating its target providing an accurate measurement of total moisture.

Radio Frequency (RF) technology uses an RF Dielectric Measurement to analyze the moisture composition of your product. The effect of moisture distribution is greatly minimized due to the RF energy deeply penetrating its target providing an accurate measurement of total moisture.

Sensortech’s patented line of RF Moisture management technologies use the Radio Frequency Dielectric Measurement and have been the standard of excellence for over 30 years. Many of these sophisticated instruments perform in the harshest environments including temperatures up to 1000°F (537°C). It is not uncommon to find these instruments still in use decades after they have been installed.

RF Technology

The RF Series of Moisture Management Systems offer unparalleled performance in a broad scope of manufacturing environments. Over 40 instruments having a variety of geometries and sizes are available to accommodate your specific manufacturing requirements. Each of these varieties of instruments are classified into one or more of the following eight series of applied RF technology:

- Open Frame Planar Series

- Flange Mount Series

- Sled Series

- Pipeline Series

- Sampling Series

- Instant Moisture Profiling System

- Packmoist

- Portable Moisture Tester

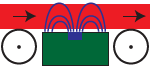

Open Frame Planar Sensor

The product passes over the sensor where the moisture measurement is taken. The open-frame minimizes buildup of debris by allowing product to fall through it and is commonly used for applications having extreme temperatures, excessive vibration, or other harsh environments. Typically used between conveying belts or rollers and In-Kiln locations.

The product passes over the sensor where the moisture measurement is taken. The open-frame minimizes buildup of debris by allowing product to fall through it and is commonly used for applications having extreme temperatures, excessive vibration, or other harsh environments. Typically used between conveying belts or rollers and In-Kiln locations.

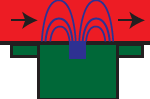

Flange Mount Sensor

The product glides on the sealed Teflon or ceramic surface of the sensor where the moisture measurement is taken. The sensor is fixed in place using the flange-mount and is placed in critical points throughout your production process. Performs well in high vibration environments and is ideally suited for granular or powdered products. Typically used in bins, hoppers, planar (sloping/horizontal) surfaces and conveyor drop-off points.

The product glides on the sealed Teflon or ceramic surface of the sensor where the moisture measurement is taken. The sensor is fixed in place using the flange-mount and is placed in critical points throughout your production process. Performs well in high vibration environments and is ideally suited for granular or powdered products. Typically used in bins, hoppers, planar (sloping/horizontal) surfaces and conveyor drop-off points.

Sled Sensor

The product passes underneath the sensor where the moisture measurement is taken. The sled hangs from hinged arms allowing it to maintain a parallel position to the conveyor and to level the product for consistent measurement. Other varieties of Sled Sensors include the Skid-Plate Sensor that has a smooth abrasion-proof surface designed to have a gentle impact on sensitive products. Typically used on conveyors (sloping/horizontal).

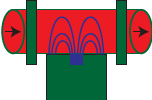

Pipeline Sensor

The product flows through the pipeline where the moisture measurement is taken. The Application Interface is made up of a pipe with an attached sensor that is integrated into the pipeline framework of the production process. A variation of the pipeline sensor is the coaxial pipeline sensor which features a center electrode providing a uniform radial field through the product to the pipe wall. An optional heater jacket ensures that the product does not solidify. Typically used with production processes manufacturing fluids, pastes, and confectionery applications.

The product flows through the pipeline where the moisture measurement is taken. The Application Interface is made up of a pipe with an attached sensor that is integrated into the pipeline framework of the production process. A variation of the pipeline sensor is the coaxial pipeline sensor which features a center electrode providing a uniform radial field through the product to the pipe wall. An optional heater jacket ensures that the product does not solidify. Typically used with production processes manufacturing fluids, pastes, and confectionery applications.

Sampling Sensor

The product enters a sampling tray or chamber where the moisture measurement it taken. A digital output of the Processor Unit is used to control the fill and purge method of sampling. Common types of Sampling Sensors include a Piston-Purge and Air-Purge Application Interface that uses different techniques of sampling the product. Sampling Sensors can be found in production processes where a small sample is taken from a large flow of product or where it is not possible to maintain a reasonably constant flow of product over the sensor.

output of the Processor Unit is used to control the fill and purge method of sampling. Common types of Sampling Sensors include a Piston-Purge and Air-Purge Application Interface that uses different techniques of sampling the product. Sampling Sensors can be found in production processes where a small sample is taken from a large flow of product or where it is not possible to maintain a reasonably constant flow of product over the sensor.

Instant Moisture Profiling System

The IMPS-4400 (Instant Moisture Profiling System) measures the true moisture content of your board product spanning the entire length and width as it passes over the IMPS-4400 Sensor Array. The Sensor Array is made up of 2 inch sensors spanning the width of the board line measuring the moisture composition across the width of the board product. Each sensor in the array scans the board product 33 times per second giving an accurate moisture measurement down the length of the board.

The IMPS-4400 (Instant Moisture Profiling System) measures the true moisture content of your board product spanning the entire length and width as it passes over the IMPS-4400 Sensor Array. The Sensor Array is made up of 2 inch sensors spanning the width of the board line measuring the moisture composition across the width of the board product. Each sensor in the array scans the board product 33 times per second giving an accurate moisture measurement down the length of the board.

The Sensor Array coupled with the rate of measurement illustrates the total moisture composition across the length and width of the board product. The IMPS-4400 identifies and stores the Kiln Deck from which each board product exits. The moisture composition of each board product from each Kiln Deck provides valuable data that is used to balance the dryer or rectify issues earlier in the manufacturing process.

Packmoist

The PackMoist Laboratory Moisture Tester uses Radio Frequency Dielectric Technology to provide an accurate moisture measurement of 20 cigarettes in their finished state of production. Simply placing a complete pack of cigarettes in PackMoist’s cylindrical test chamber provides an instant moisture measurement displayed on its Operator Interface.

The PackMoist Laboratory Moisture Tester uses Radio Frequency Dielectric Technology to provide an accurate moisture measurement of 20 cigarettes in their finished state of production. Simply placing a complete pack of cigarettes in PackMoist’s cylindrical test chamber provides an instant moisture measurement displayed on its Operator Interface.

Prior to PackMoist’s development the need to test cigarettes in their finished state of production had been accomplished through Near Infrared Reflectance (IR) laboratory gauges. This method of testing required manufacturers to carefully remove the tobacco from the cigarette casing and place the contents in its test bed. Providing a simple and non-destructive alternative to this messy and wasteful process was the objective behind PackMoist’s innovative design.

Portable Moisture Tester

Portable moisture testers satisfy a variety of needs across the spectrum of manufacturing industries. For more than 30 years Sensortech has been the standard of excellence in RF moisture testing and the latest version of the PMT-330 continues that tradition. It is very likely that you know someone who uses the PMT-330 on a daily basis.

Portable moisture testers satisfy a variety of needs across the spectrum of manufacturing industries. For more than 30 years Sensortech has been the standard of excellence in RF moisture testing and the latest version of the PMT-330 continues that tradition. It is very likely that you know someone who uses the PMT-330 on a daily basis.

The design of the PMT-330 is based on the technology used in Sensortech’s IMPS-4400 and is similar to having a portable version of its advanced technology. Using a Radio Frequency Dielectric Measurement allows the PMT-330 to penetrate the surface of the intended target and receive an accurate measurement of its moisture composition. This is a powerful capability packed into a hand-held device and why it has been the standard of portable moisture testing.