Flange Mount Moisture Sensor

The product glides on the sealed Teflon or ceramic surface of the sensor where the moisture measurement is taken. The sensor is fixed in place using the flange and is placed in critical points throughout your production process. Performs well in high vibration environments and is ideally suited for granular or powdered products. Typically used in bins, hoppers, planar (sloping/vertical/horizontal) surfaces and conveyor drop-off points.

Sealed Moisture Sensor

In a sealed sensor, an insulating material supports the center electrode, at the same time forming a flush sealed surface. Choice of insulator material depends on many factors including sanitary requirements, wear resistance and operating temperature.

Teflon Insulator

Materials include Teflon (PTFE) for food-grade applications. Teflon withstands high temperature (260°C) and is nonstick, but is quite easily worn down by abrasive materials.

Polyethylene Insulator

Ultra-high molecular weight polyethylene (UHMWPE) is also food-grade and much harder wearing than Teflon, but is limited to relatively cool applications (60°C).

Ceramic Insulator

High alumina ceramic is another useful material. It is extremely hard wearing, second only to diamond, but is brittle and not accepted in food applications. The most important consideration for any insulating material is that it must be dimensionally stable and absolutely non-hygroscopic.

Sensor Application

The most common application is located in the side of a hopper or bin such that the inside surface is flush with the inner wall of the vessel. In hopper/bin applications, it is important to maintain a fairly constant height of material above the sensor, particularly if the material is compressible since density changes as well as moisture content will influence the dielectric value. Another thing to consider with bin applications is that the flow of product is maintained over the sensor at all times. A static build-up of product on the sensor will obviously impair accuracy.

Geometries and Sizes

The Flange Mount Series is available in numerous geometries and sizes. These varieties of options give the Flange Mount the versatility of being placed exactly where your moisture measurement is needed.

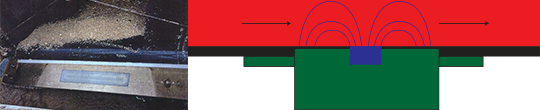

Radio Frequency (RF) Technology

Radio Frequency (RF) technology uses a Radio Frequency Dielectric Measurement to analyze the moisture composition of your product. The effect of moisture distribution is greatly minimized due to the RF energy deeply penetrating its target providing an accurate measurement of total moisture.

Sensortech’s patented line of RF moisture management technologies use the Radio Frequency Dielectric Measurement and have been the standard of excellence for over 30 years. Many of these sophisticated instruments perform in the harshest environments including temperatures up to 1000°F (537°C). It is not uncommon to find these instruments still in use decades after they have been installed.