About IR Technology

IR Technology

Near Infrared Reflectance (IR) technology employs Near Infrared wavelengths to provide a surface measurement of your products moisture composition. A well distributed moisture composition presents an opportunity for a fast, easy and dynamic measurement of virtually any product.

Near Infrared Reflectance (IR) technology employs Near Infrared wavelengths to provide a surface measurement of your products moisture composition. A well distributed moisture composition presents an opportunity for a fast, easy and dynamic measurement of virtually any product.

IR Measurement

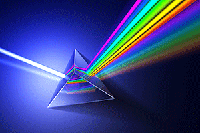

A simplified description of IR theory states that an IR light is focused on a sample and a specific wavelength is absorbed by the analyte. The reflected or transmitted light of that specific wavelength is related to the analyte concentration and used as the basis of the IR measurement.

When IR light reaches a sample several interactions can occur: the light is absorbed, reflected, or transmitted. Transmitted light will pass through the product, backscattered light will reflect from the product, and some light will be absorbed by the product. Absorbance is the key to IR measurements. The concentration of an analyte is related to the absorbance. IR instruments use either reflectance or transmittance to determine the absorbance.

Dull matte samples give diffuse reflectance while shiny mirror-like samples give specular reflectance. These reflectance interactions are generally used for measurements on solid samples. Most materials have both specular and diffuse reflectance components. Typical diffuse reflectors include dull paper, tobacco, and ceramic powders while typical specular reflectors include glossy paper, foils, and plastic sheets.

Some light transmits through thin or transparent samples either diffusely, for scattering (translucent) samples, or directly, for transparent samples. Measurements on liquids typically use transmitted light.

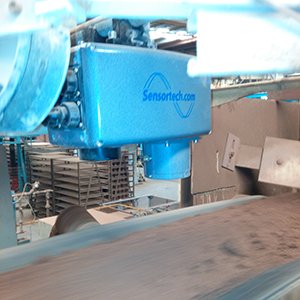

NIR 7000 Technology

Sensortech filters a quartz halogen light source into a series of pulses of specific wavelengths. The filtered beam of wavelengths is directed onto the surface of your product and measures the reflected energy against a reference source. The constituent being measured, typically moisture, is calculated through a specialized amplitude ratio algorithm providing a precision measurement based on your products molecular structure.

The NIR 7000 Series of moisture analyzer are a Moisture Measurement and Control System designed for the continuous monitoring of your product using Near Infared Reflectance (IR) technology. Its rugged design provides accurate, real-time and non-contact measurements in the most demanding manufacturing environments. The IR Series joins its precision measurement with Sensortech’s Industrial Grade Signature.

Applied NIR Technology

Will IR Technology Work On My Product?

This is the question we get all the time.

A better question is:

What technology will work on my product?.

Sensortech has been in the moisture measurement and control business for 40 years. We often find that NIR 7000 technology is the preferred method of moisture measurement. This, however, is not always the case and RF technology is sometimes a better alternative.

It is well known that Sensortech offers free laboratory analysis of our customers product. Simply fill out the following application survey and send it to our Engineering Group: info@sensortech.com

Alternatively, send us a quick note to begin your free lab analysis.