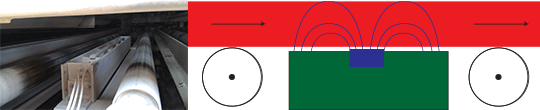

Open Frame Moisture Sensor

The product passes over the sensor where the moisture measurement is taken. The open-frame minimizes buildup of debris by allowing excess product to fall through it and is commonly used for applications having extreme temperatures, excessive vibration, or other harsh environments. Typically used between conveying belts or rollers and In-Kiln locations.

Board Moisture Sensors

The open-frame planar sensor may be used in almost all types of board plant. Gypsum plants utilize multiple sensors including high temperature sensors located in kiln zones and sensors located after the dryer.

Sensor Location

This sensor may be located between conveying rollers in a board line such that board passes over the sensor with a constant air gap, usually 6mm. The open frame design allows debris to fall through the sensor, minimizing build-up. Sensor electronics are usually attached to sensor in order to minimize cable capacitance and maximize sensitivity.

In-Kiln Sensors

Sensor electronics may be separated in high temperature locations or where vibration is excessive. Maximum sensor cable length is 5 meters. Separation of the sensor electronics from the sensor antenna provide the ability to measure moisture in extremely hot environments.

Sensor Sizes

Sensors are available in any length, but standard lengths range from 12-inch to 48-inch in 12-inch increments. Non-standard lengths are slightly higher priced.

Attached and Remote Electronics

Applications requiring extra sensitivity are available with an Attached Electronics application interface. Minimized cable capacitance achieved through combining the sensor and the electronics produces an effective moisture measurement. Alternatively, separating the sensor and the remote electronics provides the ability to operate in harsh environments.

ATTACHED ELECTRONICS

ATTACHED ELECTRONICS

Particular applications requiring high sensitivity will use an Application Interface housing having an Attached Sensor Electronics enclosure. These Application Interfaces combine the RF Sensor with the Sensor Electronics to form a single component of the Management System.

REMOTE ELECTRONICS

REMOTE ELECTRONICS

The RF Sensor (Antenna) provides the source of the Radio Frequency Dielectric Measurement. Separating the application interface from the sensor electronics provides the ability to operate in harsh environments including ultra high temperatures up to 1000°F (540°C).

Typical Industries

Sensortech’s RF Series of moisture measurement and control systems have been applied to many industries throughout the world for over 30 years. Industry demand for these instruments is due, in part, to their ability to exceed performance expectations unavailable with any other technology.

The separation of the Sensor Antenna and the Sensor Electronics provides an unmatched ability to accurately measure the moisture in an oven or kiln. This capability is highly popular with manufacturing facilities such as Gypsum Board and Ceiling Tiles.

Radio Frequency (RF) Technology

Radio Frequency (RF) technology uses a Radio Frequency Dielectric Measurement to analyze the moisture composition of your product. The effect of moisture distribution is greatly minimized due to the RF energy deeply penetrating its target providing an accurate measurement of total moisture.

Sensortech’s patented line of RF moisture management technologies use the Radio Frequency Dielectric Measurement and have been the standard of excellence for over 30 years. Many of these sophisticated instruments perform in the harshest environments including temperatures up to 1000°F (537°C). It is not uncommon to find these instruments still in use decades after they have been installed.