ST-3300

The ST 3300 is the next generation of process moisture measurement and control. Sensortech’s patented radio frequency measurement principle enhanced by all-digital phase lock loop signal conditioning presents a radically improved standard of resolution and stability. Signal processing capabilities are integrated into the Transmitter Electronics. The Transmitter Electronics interfaces directly to your PC, PLC, HMI, or other preferred platform. User-friendly configuration software manages the operation of the ST 3300 through your PC.

The ST 3300 advances Sensortech’s patented phase lock loop dielectric measurement technique. Digital conditioning provides a radically improved standard of resolution and stability. Additionally, internally switched standards offer long-term stability while two-term ratio measurements eliminate the influence of density in many applications.

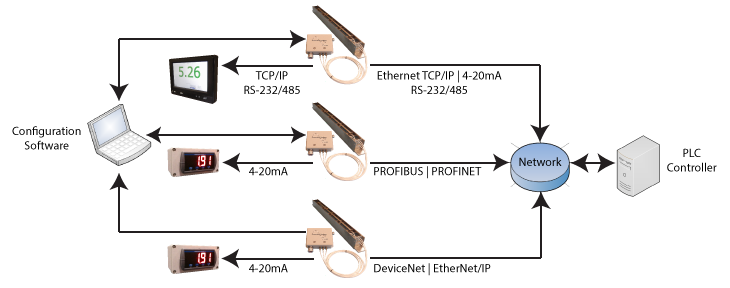

All Proprietary Networks

| Standard I/O | Advanced I/O |

| RS-485 Full Duplex | Ethernet TCP/IP |

| 4-20mA Analog Output | PROFIBUS |

| Digital Input | PROFINET |

| Product Temp Input | DeviceNet |

| EtherNet/IP |

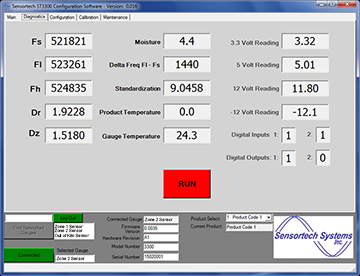

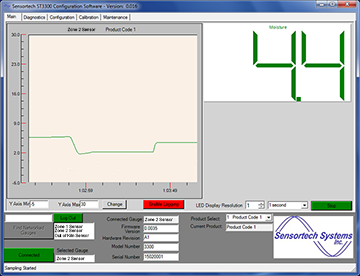

USER-FRIENDLY CONFIGURATION SOFTWARE

The ST 3300 includes a powerful configuration software package that provides management utilities for all sensors in your process from a laptop or PC. The configuration software is password protected for engineers and provides numerous functions for operators. Operator functions include a graphic display and a data-logging feature that allow the operator to save historical data to a file that can be opened with spreadsheet applications such as Microsoft Excel for statistical analysis. Additionally, the operator can connect to all sensors in your plant from the Configuration Software and select up to 50 stored calibrations (product codes). Operators have access to the sensor Diagnostics Screen that provides a snapshot of the sensor’s health.

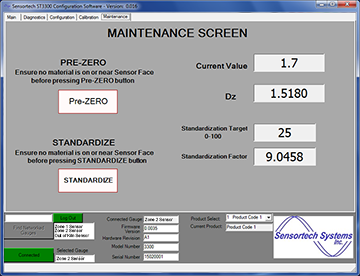

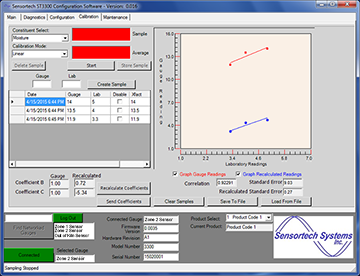

CALIBRATION & STANDARDIZING UTILITIES

The Configuration Software package includes a calibration utility that simplifies the process of calibrating all of your products. The calibration utility automatically calculates the span and offset coefficients and saves it to one of fifty product codes making the calibration process quick and easy. Standardizing your sensors is equally as simplified using the Maintenance Screen. Select the targeted sensor from your network from the Configuration Software and standardize your sensor.

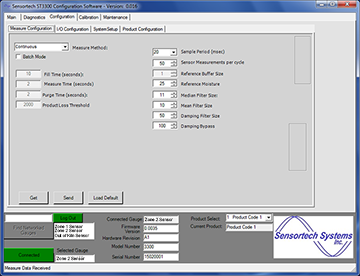

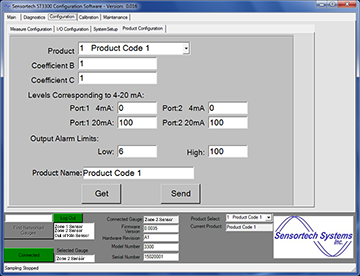

PRODUCT & MEASUREMENT UTILITIES

Among the many configuration utilities included with your Configuration Software package are the product and measurement utilities. These utilities provide several methods of measurement filtering: sampling periods, measurement per cycle, buffering size, median and mean filtering, and damping. Additionally, the ST 3300’s intelligent sampling methods include: continuous, sampling on command, timed sampling, and automatic product detection. Setting alarm limits for high and low moisture levels is another feature easily configured using the Configuration Software package.

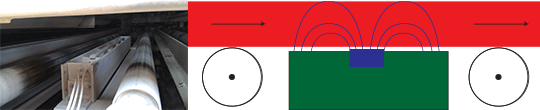

Open Frame Series

The product passes over the sensor where the moisture measurement is taken. The open-frame minimizes buildup of debris by allowing product to fall through it and is commonly used for applications having extreme temperatures, excessive vibration, or other harsh environments. Typically used between conveying belts or rollers and In-Kiln locations.

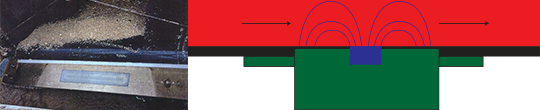

Flange Mount Series

The product glides on the sealed Teflon or ceramic surface of the sensor where the moisture measurement is taken. The sensor is fixed in place using the flange-mount and is placed in critical points throughout your production process. Performs well in high vibration environments and is ideally suited for granular or powdered products. Typically used in bins, hoppers, planar (sloping/horizontal) surfaces and conveyor drop-off points.

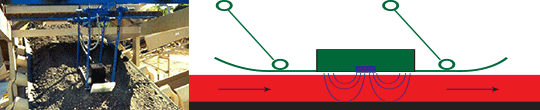

Sled Series

The product passes underneath the sensor where the moisture measurement is taken. The sled hangs from hinged arms allowing it to maintain a parallel position to the conveyor and to level the product for consistent measurement. Other varieties of Sled Sensors include the Skid-Plate Sensor that has a smooth abrasion-proof surface designed to have a gentle impact on sensitive products. Typically used on conveyors (sloping/horizontal).

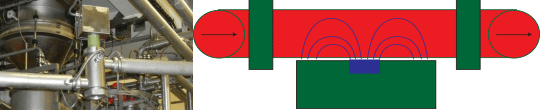

Pipeline Series

The product flows through the pipeline where the moisture measurement is taken. The Application Interface is made up of a pipe with an attached sensor that is integrated into the pipeline framework of the production process. A variation of the pipeline sensor is the coaxial pipeline sensor which features a center electrode providing a uniform radial field through the product to the pipe wall. An optional heater jacket ensures that the product does not solidify. Typically used with production processes manufacturing fluids, pastes, and confectionery applications.

Sampling Series

The product enters a sampling tray or chamber where the moisture measurement it taken. A digital output of the Processor Unit is used to control the fill and purge method of sampling. Common types of Sampling Sensors include a Piston-Purge and Air-Purge Application Interface that uses different techniques of sampling the product. Sampling Sensors can be found in production processes where a small sample is taken from a large flow of product or where it is not possible to maintain a reasonably constant flow of product over the sensor.