Options

TEMPERATURE CONTROL

Sensortech’s IR Series design is enhanced with an efficient light source that captures more than 80% of usable energy. Effective use of power dramatically increases optical efficiency enabling the instrument to run significantly cooler. The reduced operating temperature inherently reduces stress on electronics and power supplies, increases the life of the instrument and further reduces excessive costs associated with added temperature conditioning.

Many environments, however, where the IR Series are implemented exceed its normal operating temperature. The design of Sensortech’s IR Series lends itself to high temperatures where a simple cooling option will satisfy its ambient temperature operating requirements. Environments having an extremely high ambient temperature require an NIR-6300 Series IP67 Moisture Analyzer.

Additionally, Sensortech offers a Heating Option for environments having an ambient temperature below the standard operating temperature of the IR Series analyzer.

A number of options are available to increase or decrease the standard operating temperature limits:

| OPTION | SPECIFICATION |

| Standard Operating Temperature | 32 to 131°F (0 to 55°C) |

| Air/Liquid Cooling Panel | 32 to 185°F (0 to 85°C) |

| 6300 Series Air/Liquid Cooling | 32 to 185°F (0 to 85°C) |

| 6310 Series Insulated Liquid Cooling | 32 to 221°F (0 to 105°C) |

| Heating Option | -4 to 131°F (-20 to 55°C) |

* Contact Sensortech for additional options

APPLICATION INTERFACES

Applying IR technology to your process is accomplished through Sensortech’s numerous application interfaces. These interfaces have been developed for specialized applications to apply IR technology in various process locations. Examples of these process locations include: belt conveyors, conveyor drop-off points, down chutes, drag conveyors, fluid-bed dryers, hoppers, planar surfaces, roller conveyors, screw conveyors and storage bins.

The IR Series are intrinsically equipped to be mounted in nearly every location of your production process. The IR Series analyzers are simple to install and easy to operate giving the flexibility to place its productivity enhancing benefits where it is needed most.

The following are a sample of the most common interfaces that have been implemented throughout the globe:

Flange Mount

Moisture measurement of closed conveyor equipment providing moisture control of a continuous flow of product. Product maintains contact with the abrasion resistant non-hygroscopic window ensuring an accurate real-time measurement.

Snorkel Sampler

Snorkel Sampler

Intelligent sampling method of measurement provides moisture control of inconsistent product flow. The Snorkel protrudes into the product flow, collects a sample for measurement and purges the sample for the next measurement.

A variable mounting clamp provides an adjustable penetration depth into the bulkhead allowing the flexibility of positioning the sample cup in the product flow.

Timed Sampling measurement technique used in conjunction with user defined fill and purge controls adapt to numerous flow rates.

COMMUNICATION PROTOCOLS

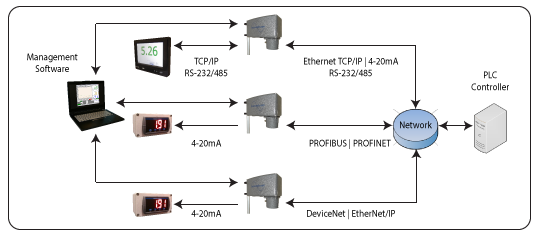

All IR Series Moisture Analyzers include standard features of communication that include three self-powered isolated 4-20mA outputs, RS-232, Ethernet TCP/IP and RS-422/485 protocols. Optionally, the IR Series offers a number of additional communication protocols:

PROFIBUS

PROFIBUS- PROFINET

- DeviceNet

- EtherNet/IP

Network Configuration

Network Configuration

The IR Series Moisture Analyzers support all major proprietary networks.

Sensortech’s Management Software provides configuration utilities to set your network parameters. Simply connect your PC or Laptop to the IR Series Analyzer, run Sensortech’s Management Software and setup your network configuration.