Powdered Material

Moisture in Powdered Products

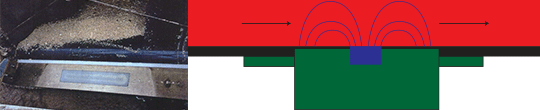

The continuous online moisture measurement of powdered products is perhaps the best application for Sensortech moisture instruments. Powder exiting a mixer or screw conveyor, for example, is ideally prepped for measurement. After the powder has been thoroughly agitated its moisture distribution throughout the whole of the product is evenly represented on the surface of the powder. This presents an ideal opportunity for Sensortech’s NIR-6000 Series Analyzer to measure the moisture of the powder.

Sensor Locations

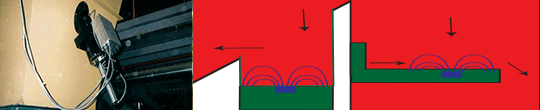

Sensortech’s IR Series Analyzers are non-contact instruments designed to operate 4 to 16 inches from the target measurement area. This mode of operation is highly versatile and allows the measurement to be taken where it is needed. Simply mounting the analyzer above an open conveying system such as a drag conveyor is all that is needed for operation. Alternatively, Sensortech offers an array of Application Interfaces that will mount to closed conveying systems as well.

Explosion Proof Instruments

Powdered products or fine granular materials often create a hazardous environment where explosion proof instruments are required. Typically, an instrument with a minimum rating of Class II is required for locations where combustible dust is found. Sensortech’s NIR-6410 Series Moisture Analyzers are pressurized and allow it to comfortably operate in these types of hazardous locations.

Alternative RF Moisture Sensors

IR technology will not always suffice for moisture measurement applications of powdered materials. There are circumstances where the surface of the product is not representative of the whole of the product. In these cases, a penetrating measurement may be required.

Sensortech exceeds where conventional instrument manufacturers fail. Sensortech’s strength is in its broad array of moisture measurement and control technologies. IR and RF technologies both have their strengths and weaknesses and finding the best fit for each application is our specialty. Adapting the correct technology to an application is essential to the feasibility and accuracy of the measurement. If the process is not suited to the surface measurement of IR than an RF instrument may be better suited to your process.